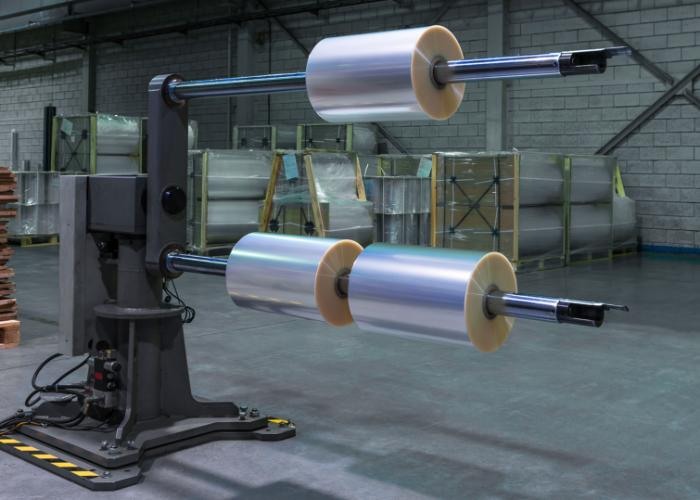

Dotec is a family owned business since 1981 that is leading with many years of experience in delivering customized, high-quality roll handling solutions. Through our in-depth knowledge of manufacturing processes and close collaborations with machine builders, producers, processors, and end users, we have developed an extensive range of handling equipment specifically designed to increase output, minimize downtime, and improve safety and ergonomics. The roll handling equipment is easy to use, reliable, and can move rolls up to 600 kg with minimal physical effort.

Dotec responds to the industry trend of automated and semi-automated roll handling equipment. Our handlers for rolls help companies to smoothly transition from manual to automated and semi-automated handling. This results in less physical strain for the staff, less downtime, and faster production processes, contributing to a good return on investment and work satisfaction. With our solutions, we guarantee convenience and a pleasant working experience.

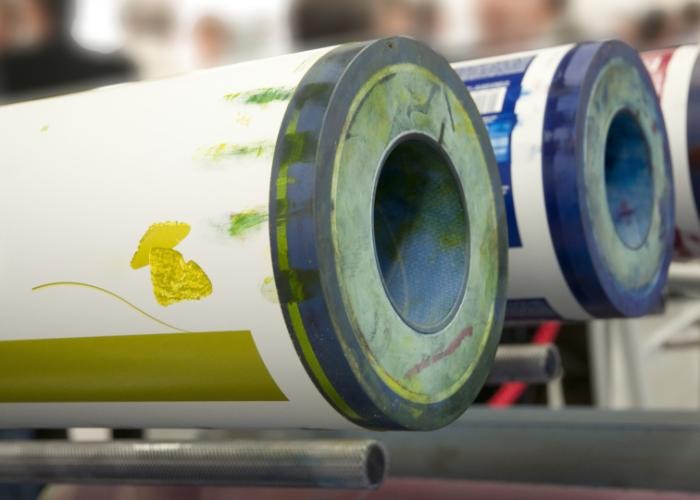

We have the right handling equipment for you whether you are active in the Flexible packaging, Label & narrowweb, Hygiene & nonwoven, Yarn & textile, Printing sleeves, Shafts, Paper and stretch film industry. Contact us today and discover how our solutions can transform your organization.